Products1

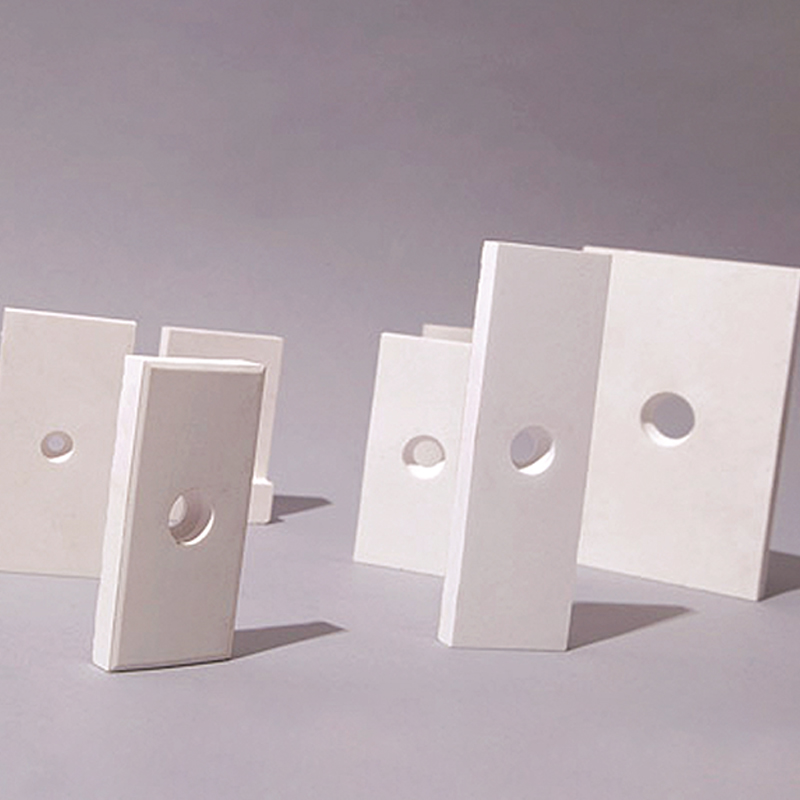

Hicera High quality Alumina grinding balls

Hicera grinding media is characterized by:

-HIGHER DENSITY

-HIGHER HARDNESS

-HIGHER WEAR RESISTANCE

-HIGHER GRINDING EFFICIENCY

We could offer defferent type of products and costs-effective solutions for different kind of grinding. Such as body grinding, glaze grinding, mineral, ink, etc, require different kinds of grinding media. We are expertise at application at different kind of ballmill, such as batch ball mill, continouse ball mill, modular ball mill, sand ballmill, HIG mill etc,. We welcome your contact and discussion to get the best and cost-effective solutions for your grinding process.

Alumina grinding media products type as below for referance:

CHEMICL COPOSITION | HCR PLUS | HCR 92S | HCR 92DR | HCR Alubeads | HCR 75 | HCR 70 |

AL2O3 (%) | 92.5±0.03 | 92±0.03 | 92±0.03 | 92±0.03 | 75±1 | 68±2 |

Bulk density (g/cm3) | 3.68 ±0.03 | ≥3.66 | 3.63±0.03 | 3.68±0.02 | 3.30±0.05 | 3.05±0.05 |

Wear rate (%) | ≤ 0.006 | ≤ 0.009 | ≤ 0.01 | ≤ 0.003 | ≤ 0.012 | ≤ 0.018 |

Hardness (Mohs) | 9 | 9 | 9 | 9 | 8.9 | 7.8 |

Water absorption (%) | 0 | 0 | 0 | 0 | 0.5 | 0.8 |

Color | White | White | White | White | Light gray | Beige |

Recomend Size | 15-30mm | 20-70mm | 17-80mm | 0.2-20mm | 30-70mm | 30-70mm |

Grinding methord | wet grinding | wet grinding | Dry grinding | wet | wet | wet |

Hicera

can offer the following services, in order to optimize the grinding process according to the needs of partners and the features of their production facilities.

Grinding charge sizing and optimizing

Lining sizing and optimizing

Indications of the most suitable ball quality

Welcome contact via email office@hiceraindustrie.com or call us to get more detials and solutions.

Products

Contact Us

Company: HICERA INDUSTRIE GROUP CO.,LTD

Tel: 86-13355334629

E-mail: sales@hiceraindustrie.com

Add: 221 West Gongqing Tuan Road, Zibo City, Shandong, China.